Welcome to

Bench2Batch™ delivers expert CMC process development and MSAT support—covering scale-up, tech transfer, process characterization and validation—across the biopharma lifecycle.

We help move your product from bench to commercial launch, and support ongoing manufacturing with robust Continuous Process Verification systems.

Why Bench2Batch™

Bench2Batch is led by Naveenganesh Muralidharan,

Biopharmaceutical leader with 20+ years of experience in GMP manufacturing, tech transfer, and end-to-end process validation across biologics, gene therapy, oligonucleotides, and RNA modalities. Proven in advancing programs from early development through commercial launch, leading MSAT, CQV, and process scale-up with strong FDA/EMA compliance. Extensive expertise in Upstream, Downstream, batch record authoring/review, data trending, deviation and change control, and on-site CMO campaign support. Recognized for first-time-right execution, cross-functional leadership, and driving robust supply chains and secondary vendor transfers to ensure reliable global manufacturing.

You get more than documentation — you get a true technical partner.

Technical Insights

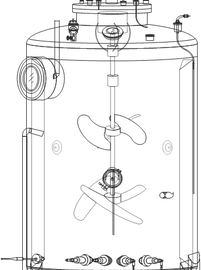

On-Line Bioreactor Scale-Up & Scale Down Tools

These online bioreactor calculators simplify the process of scaling up or down between bench and production scale. They offer tools to predict pCO2, assess shear from impellers and sparging, and

calculate OTR and KLa. This helps users optimize process conditions and improve scalability

across different reactor sizes.